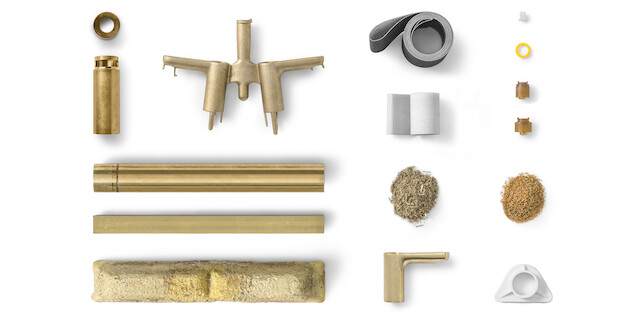

FROM MATTER TO FORM

FOUNDRY, MECHANICAL MACHINING, POLISHING, THERMOPLASTIC MOULDINGS

Nobili, the only European company in the sector with a fully integrated production cycle, is stable as a leader in the industry. It is in the highest position for research activities and, above all, for the level of technological evolution of its production systems.

1000° TECHNOLOGY

The only fully automated plant in the industry: the Foundry department, the pride and joy of the Nobili technology.

MECHANICAL MACHINING

120 facilities produce more than 28 million components a year from a bar of brass, in an environmentally friendly manner without waste: all stages are controlled by an electronic system that guarantees absolute precision, an essential element for furnishing the most prestigious homes and hotels in the world.

ACES UP YOUR SLEEVE

Maniacal precision and high machining speed, an expression of pure technological advancement: the CNC multi-axis turning centre.

POLISHING

After the Foundry and Machining phases, the components are thoroughly washed and then move to the Polishing department: in this area, 110 fully automated stations process more than 6 million components per year, coordinating the automation of the robots with the great experience of the dedicated operators.

SMOOTH AND SHINY

Perfectly smooth and shiny surfaces thanks to fully automated systems: the Polishing Department.

THERMOPLASTIC MOULDINGS

Plastic components play a fundamental role: the cartridge, in particular, is made using special food-mix plastic that is completely free of toxic elements. A department of excellence with 18 presses, processing more than 15 million components per year, non-stop (24 hours a day) and with no waste.

PLASTIC SURGERY

The thermoplastic moulding department is one of the most advanced in the industry.